Foil stamping is a popular technique in book printing, adding a luxurious, metallic finish to your cover. It enhances a book’s aesthetic appeal, making it stand out on shelves. Two primary methods exist: traditional foil stamping and digital foil stamping. While both achieve stunning results, they differ significantly in process, cost, flexibility, and application. This blog post explores these differences to help you make an informed decision about your book.

What is Foil Stamping?

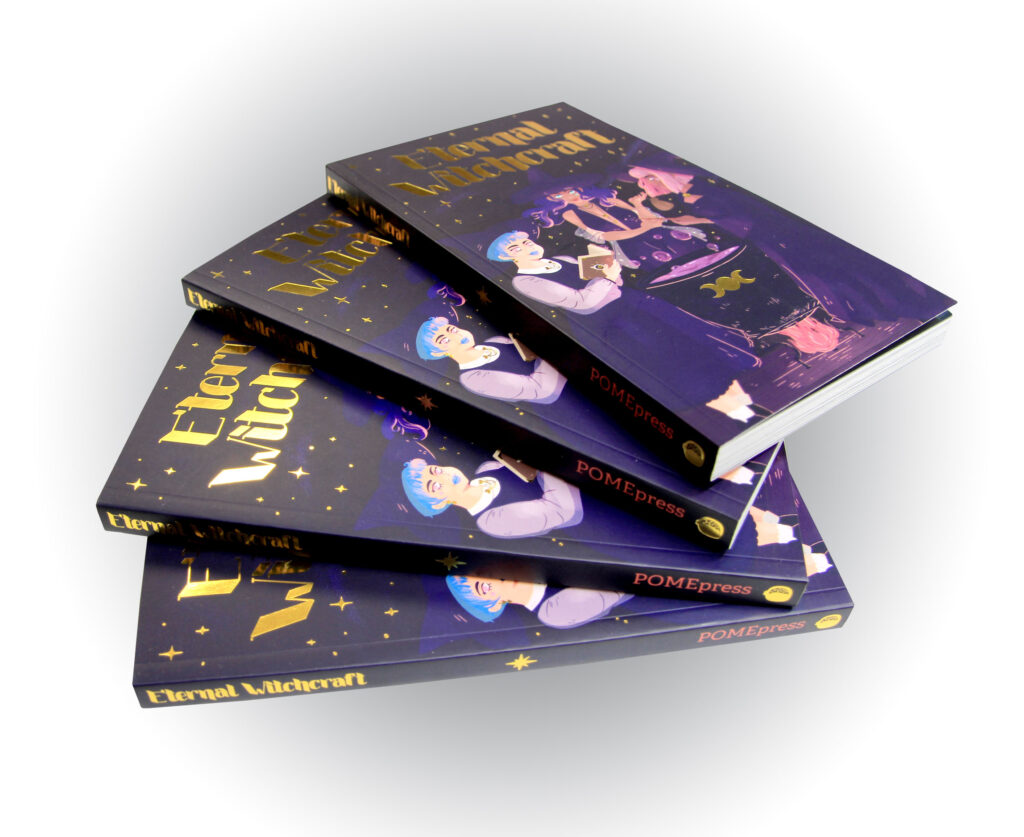

Foil stamping applies metallic or colored foil to a surface using heat, pressure, and a stamping die or plate. The foil adheres to the substrate (typically cardstock or hardcover material), creating a shiny, reflective design. It’s commonly used for book titles, logos, or decorative elements, giving books a premium look.

Traditional Foil Stamping

Process

Traditional foil stamping, also called hot foil stamping, involves:

- Creating a Metal Die: A custom metal die (or stamp) is engraved with the desired design.

- Heating the Die: The die is heated and pressed against a roll of foil.

- Applying Pressure: The heated die transfers the foil onto the book’s surface, bonding it permanently.

Advantages

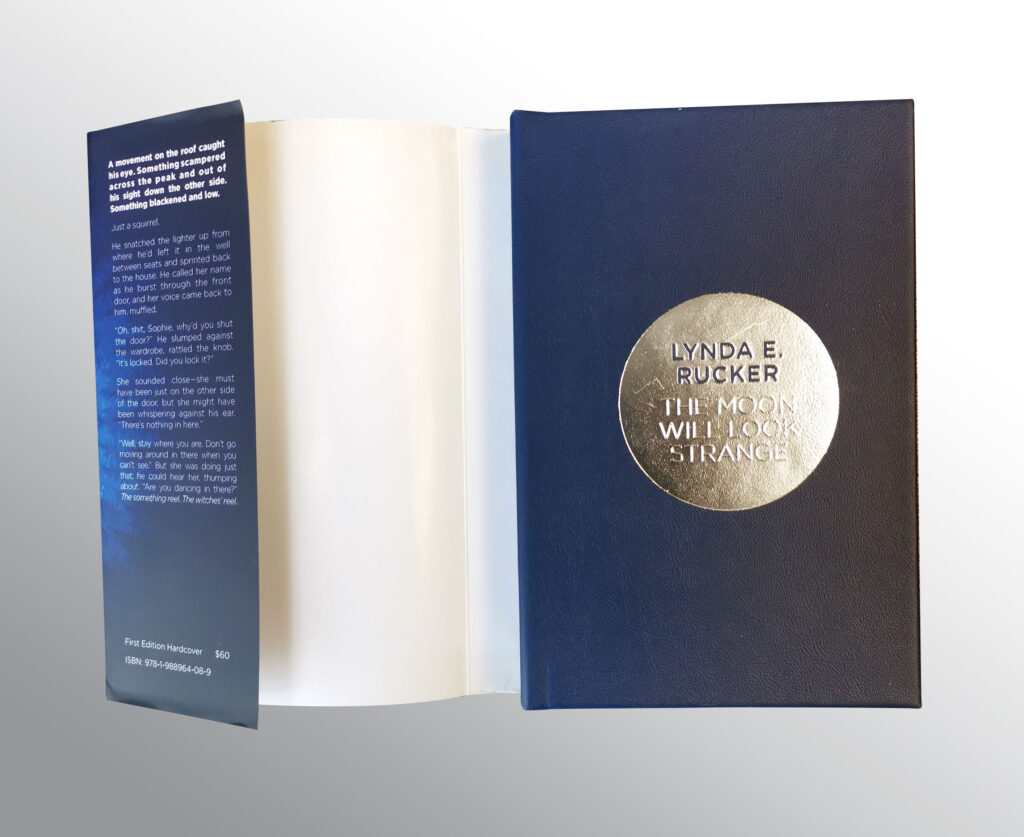

- High-Quality Finish: Traditional stamping produces crisp designs with a tactile, debossed effect. Also, it will be slightly more reflective than digital foil.

- Durability: The foil bonds strongly, resisting wear over time.

- Wide Material Compatibility: Works on various substrates, including leather, cloth, and paper.

- Large Volume Efficiency: Cost-effective for high print runs due to the reusable die.

Best Use Cases and Potential Outcomes

Traditional foil stamping is ideal for large print runs of books with consistent designs, such as hardcover editions of bestsellers or special collector’s editions. Its durability and premium finish suit projects where quality outweighs cost considerations.

It is important to note that designs that include fine lines or intricate patterns may not transfer well with hot foil stamping.

Digital Foil Stamping

Process

Digital foil stamping, also called cold foil stamping, is a modern, technology-driven alternative that eliminates the need for physical dies. The process includes:

- Digital Printing Base Layer: A digital printer applies a specialized adhesive or toner in the shape of the design.

- Foil Application: Foil is pressed onto the adhesive areas, typically using a heated roller.

- Finishing: The foil bonds only to the adhesive, creating the final design.

Advantages

- No Dies Required: Eliminates costly die production, reducing setup expenses.

- Short-Run Friendly: Cost-effective for small batches or print-on-demand books.

- Quick Turnaround: Designs can be created and modified digitally, speeding up production.

- Complex Designs: Allows for more intricate foil designs.

Best Use Case and Potential Outcomes

Digital foil stamping suits small to medium print runs, self-published books, or projects requiring customization. It’s perfect for limited editions, promotional copies, or books with tight deadlines.

When using digital foiling, there is a potential for the foil to stick to other parts of the cover, causing a “sparkle effect”. This is more commonly observed on books with soft-touch matte lamination.

Trends in Book Printing

The rise of digital printing technologies has made digital foil stamping increasingly popular, especially among indie authors and small publishers. However, traditional foil stamping remains the gold standard for luxury editions, such as leather-bound classics or anniversary releases.

Conclusion

Both traditional and digital foil stamping elevate a book’s visual appeal, but they cater to different needs. Traditional stamping offers unmatched quality and durability for large-scale, premium projects, while digital stamping provides affordability, speed, and customization for smaller runs.

Ready to add some shine to your next book project? Ask us about our foil stamping options and bring your design to life!