The covers of a book is often the first point of contact between a reader and the story within. Understanding the various materials used in book cover printing unveils a world of choices, each with its unique characteristics, impacts, and applications. Let’s dive into the universe of some cover materials and their roles in the printing process.

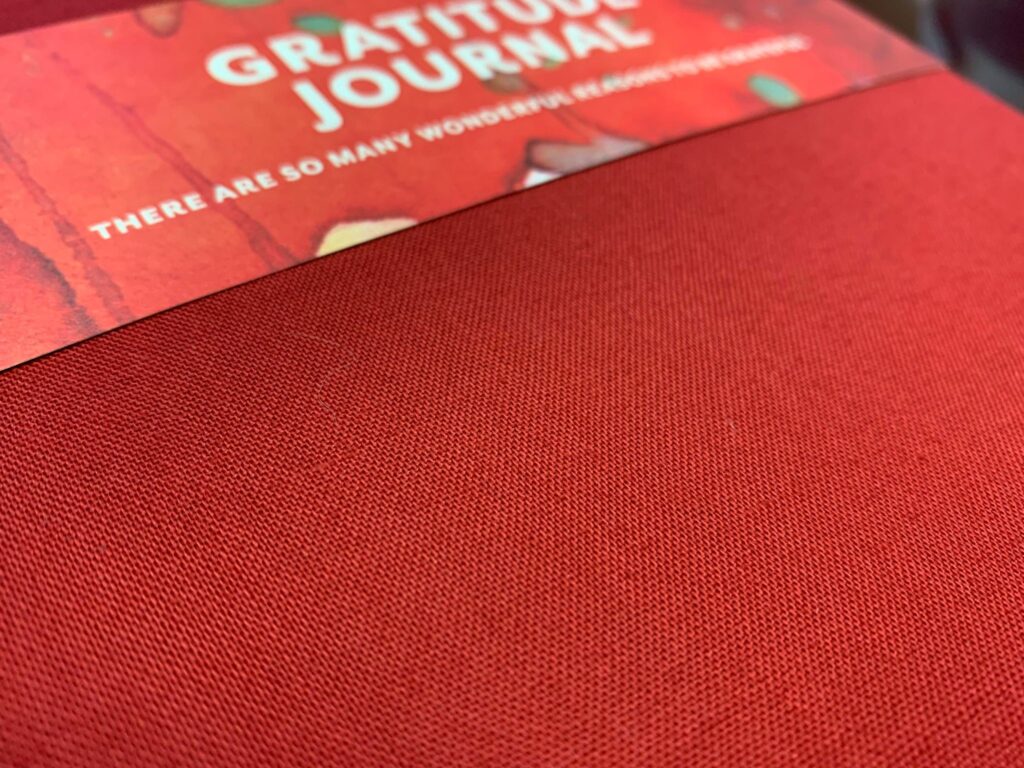

Coated Stock with Lamination

Coated stock offers a sturdy base for showcasing vibrant designs. With different laminations like matte, gloss, or soft-touch silk, it enhances the visuals and adds a layer of protection against wear and tear. Choosing the right lamination can influence the look and feel of the cover, offering various textures and finishes for the reader.

Cloth/Linen Covers: A Touch of Elegance

Within the realm of casebound, flexibound, and hardcover wire-o books, cloth and linen covers offer a distinctive and enduring presence. These materials boasts a textured, sophisticated finish that not only captivates the eye but also guarantees longevity. Their enduring aesthetic makes them the preferred choice for publications aspiring to create a lasting impact and unique identity.

Choosing the Fibers: Cloth production involves selecting natural fibers such as cotton, wool, or silk, along with synthetic fibers like polyester, rayon, or nylon, based on the desired cloth properties. While linen specifically refers to a fabric made from the flax plant.

Both cloth and linen have variations in their production processes depending on the specific fibers used and the desired characteristics of the final fabric. These processes are part of the broader textile industry and may involve different techniques and machinery based on the type of cloth or linen being produced.

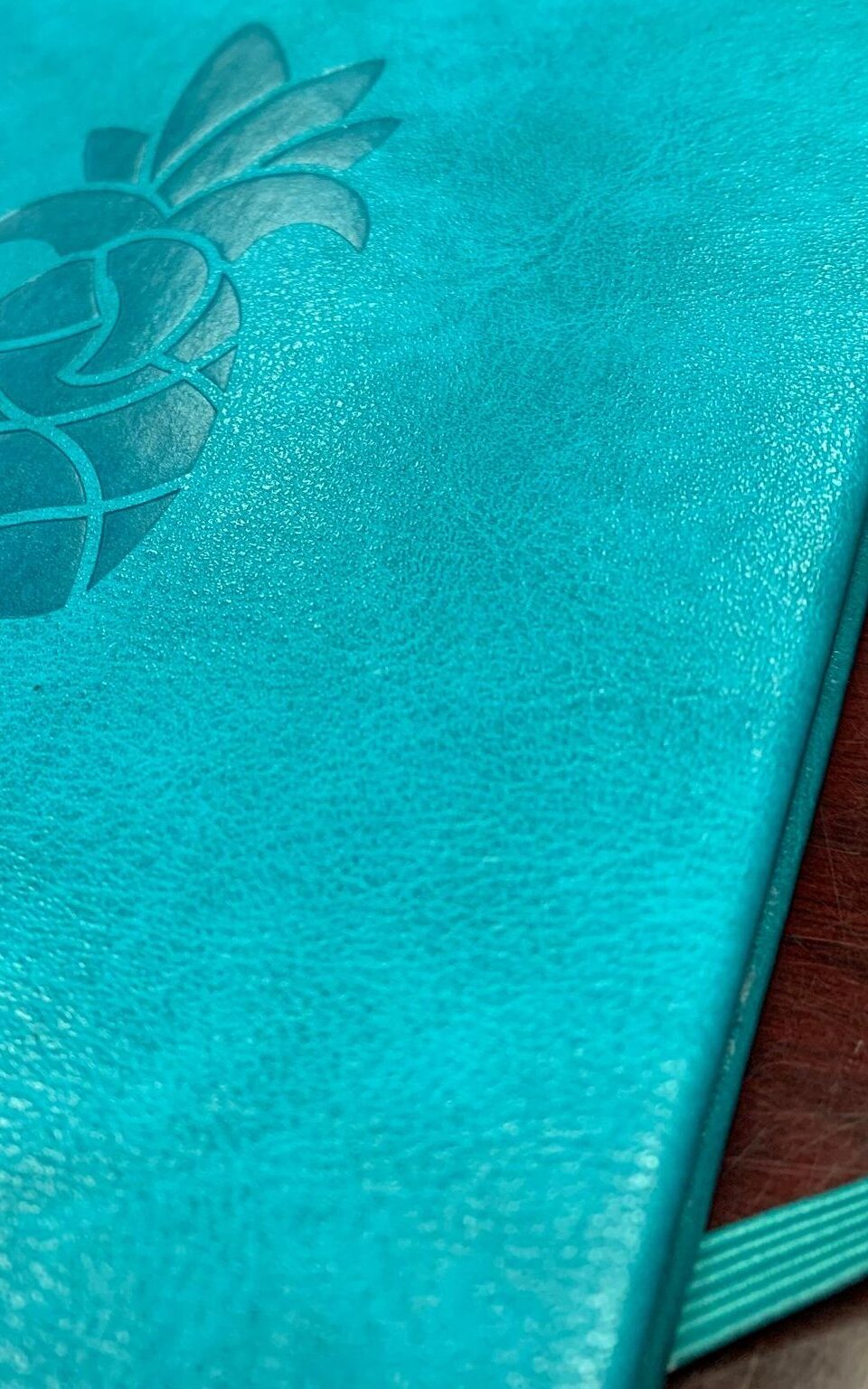

Imitation or Vegan Leather Covers

For special editions or those seeking a touch of luxury without the expense of genuine leather, imitation leather or vegan leather covers provide an elegant alternative. The material is a fabric based, often polyester or cotton serves as the foundation, coated or immersed in a polymer such as polyurethane (PU) or polyvinyl chloride (PVC). Mimicking the look and feel of real leather, these covers are sophisticated, making them a great choice for a variety of book genres.

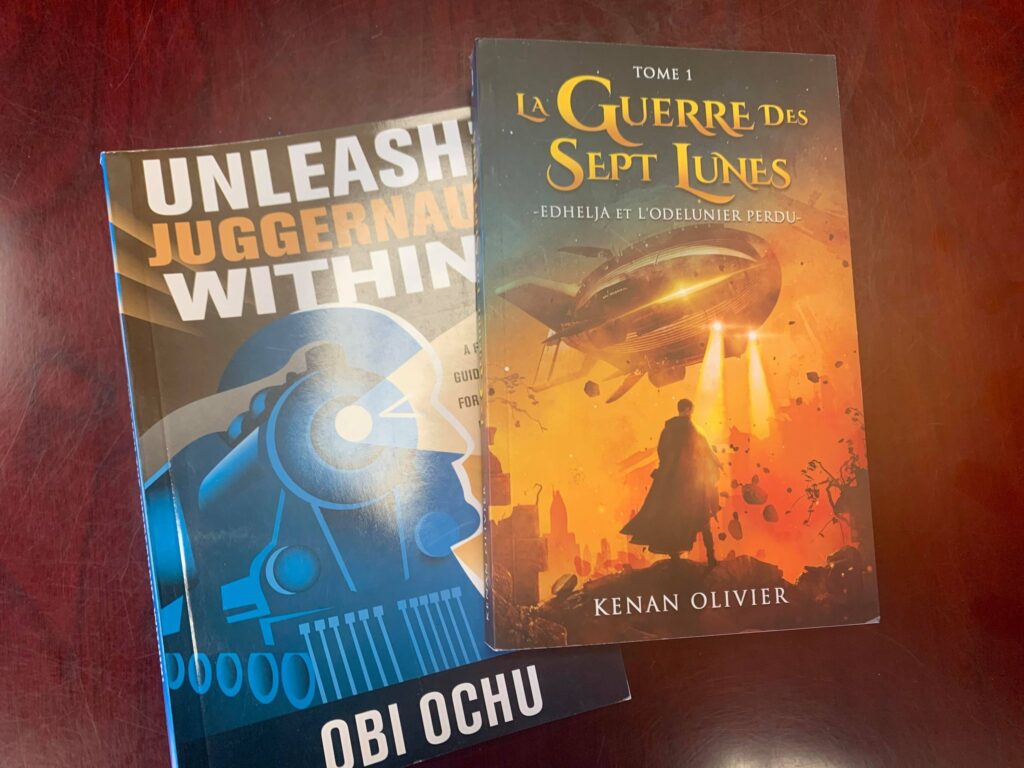

Comparison: Hardcover vs. Softcover Books

Softcover books typically use cardstock with thickness options ranging from 10pt to 16pt, providing a flexible and lighter touch. The addition of lamination influences the overall thickness, contributing to the durability of these covers and delivering a professional appearance.

Hardcover books, on the other hand, uses sturdier materials, such as 2.5mm or 3mm greyboard, paired with a 100lb coated stock cover. This construction provides not just visual appeal but protection for the book’s content.

Construction of Softcover Books

Softcover books aka paperback, is more flexible compared to the materials used in hardcover books, allowing the cover to bend easily, providing a lighter and more pliable feel.

The cover material is commonly paired with a finish, such as soft touch silk, matte or gloss lamination, which not only enhances the cover’s aesthetics but also adds a protective layer.

In the binding process, the cardstock cover is attached to the book’s contents, usually through glue (EVA or PUR), which secures the cover to the inner pages. Softcover book construction is designed to provide flexibility and a lighter weight, allowing for easier handling and comfortable reading experiences.

This construction style is often preferred for various genres and publications, offering cost-effectiveness and easy portability while still maintaining an attractive and professional appearance.

Hardcover Book Construction

Hardcover book production is a more meticulous process, with the cover printed on a coated stock or leather/cloth/linen, and then precisely wrapped around a sturdy greyboard. The adherence of the cover to the greyboard requires precision to ensure a seamless finish, making hardcovers a popular choice for lasting quality.

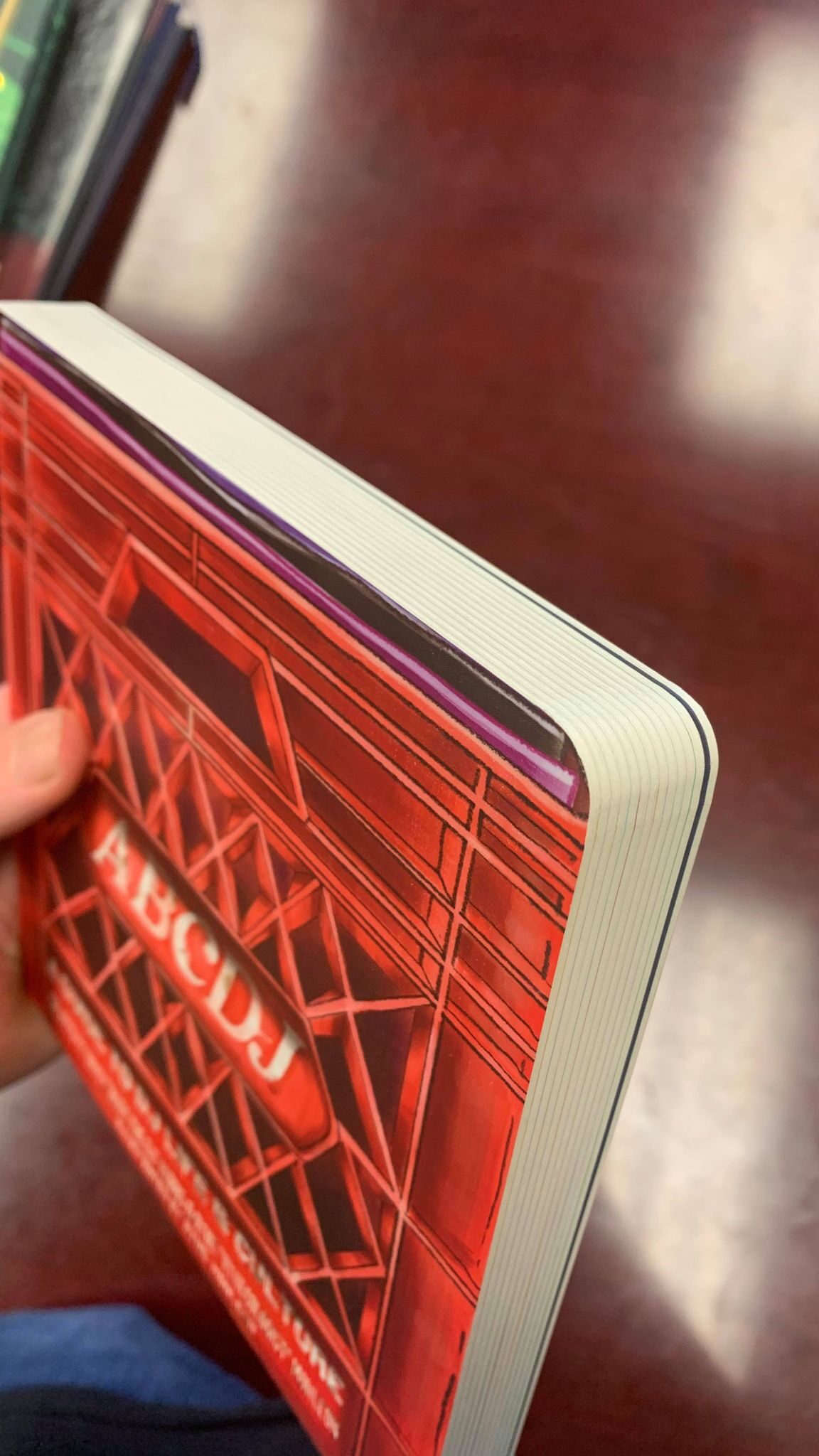

Board Book Covers

In board books, the cover material matches the inside pages, providing a consistent and sturdy feel. These materials are designed for younger readers and ensure durability throughout; to be able to handle the wear and tear of young hands.

Conclusion

Understanding the diverse range of materials and their applications in book cover printing is essential for authors, publishers, and designers. The cover isn’t merely an introduction to the book but a statement of its quality, resilience, and visual appeal. Choosing the right material and understanding its implications play a significant role in making a lasting impact on readers.

Understanding the significance of these materials and their creation procedures empowers authors, publishers, and designers to ensure that the cover not only engages but endures, leaving a lasting impact on readers.